No products in the cart.

Article

Best Dental Milling Machines for Same-Day Crowns and Restorations (2026 Guide)

In a field where results and efficiency matter, speed, accuracy, and patient satisfaction are essential. They’re essential pillars of success.

Dental milling machines have changed the way we restore smiles. They make it faster and easier to create perfect, custom restorations in-house. As more dentists seek advanced chairside solutions, dental milling technology is quickly becoming the gold standard.

This guide examines the Top dental milling machines in contemporary dentistry. It explains how they help create new dental solutions and which machines give the best results. If you’re considering upgrading your equipment, now is an ideal time to discover how this technology can benefit your practice.

Continue reading to discover top features, leading products, and learn how to select the ideal system for your specific needs.

What Is a Dental Milling Machine?

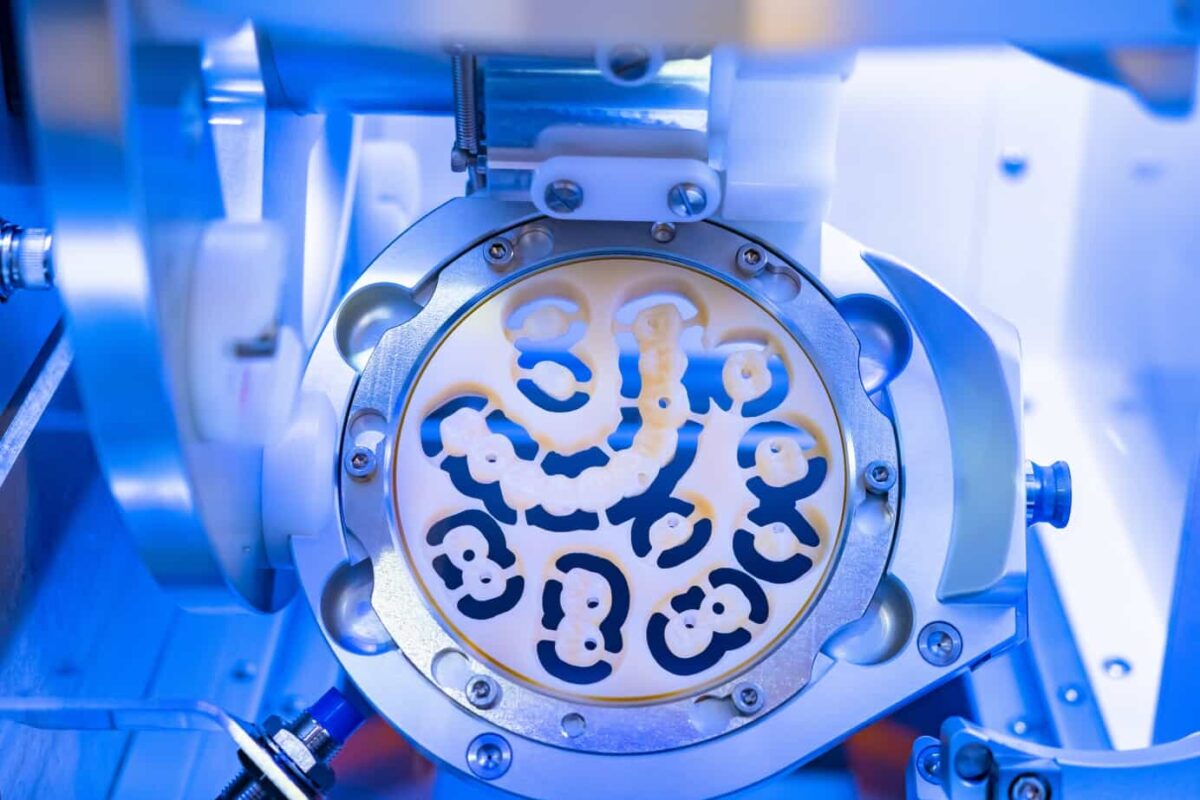

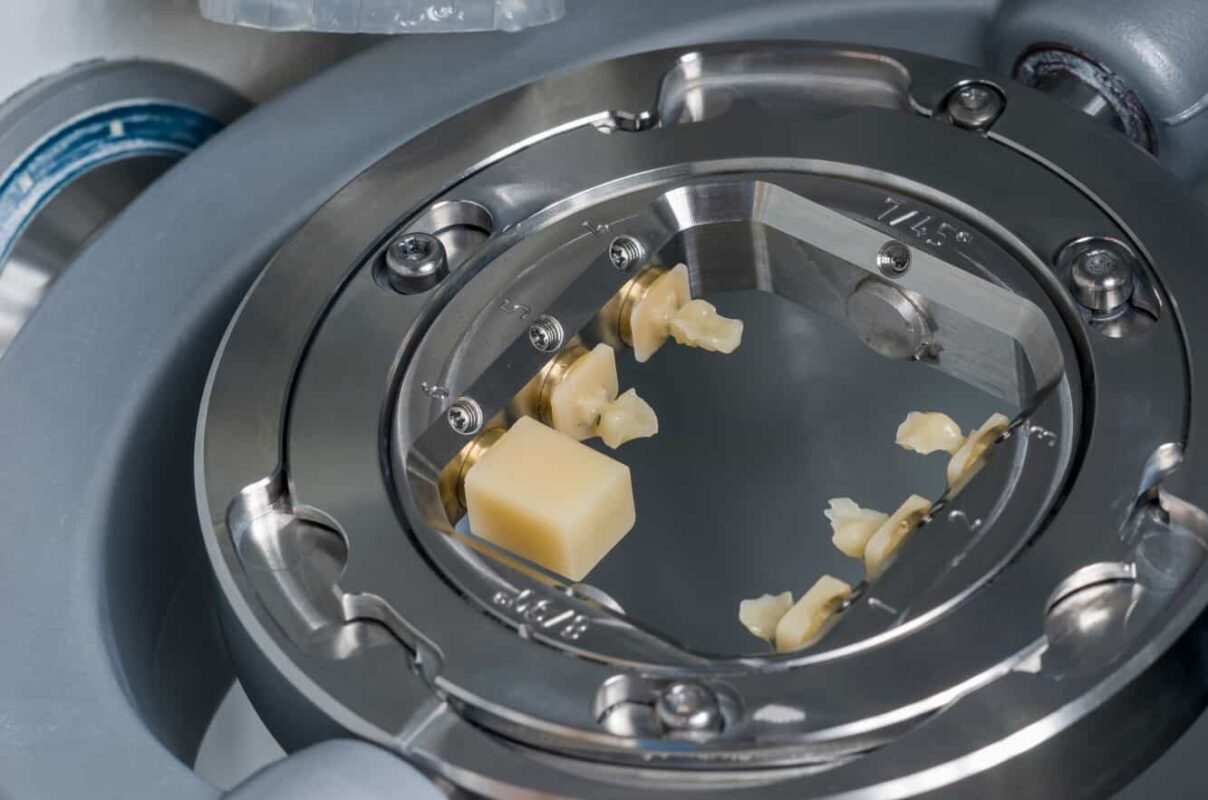

Dental milling machines are computer-controlled tools. They create many types of dental restorations. These include crowns, bridges, inlays, onlays, and implant abutments. These machines use fast rotary tools or diamond-coated bits to shape pre-made blocks of material from digital CAD designs.

By automating the fabrication process, they eliminate many manual errors and reduce the need for adjustments during placement. Common materials include:

- Zirconia

- Ceramic

- PMMA

- Composite resin

- Titanium

Each is selected for its durability, esthetics, and compatibility with different types of restorations.

These machines deliver restorations with micron-level accuracy. They ensure the following:

- Excellent marginal fit

- Long-lasting performance

- Patient comfort

They support both wet and dry milling processes, making them versatile for various clinical and laboratory applications. This level of precision and automation enables dentists to produce reliable, high-quality results while saving time and enhancing patient outcomes.

These machines are a critical part of the digital workflow that begins with intraoral scanning. Once a patient’s oral structures are scanned, the files are processed using CAD (Computer-Aided Design) software. The design is then transferred to the dental milling machine, which fabricates the restoration with extreme accuracy.

Materials commonly used:

- Zirconia

- Lithium disilicate

- Composite resin

- PMMA

- Titanium

Compatible systems:

- CAD/CAM integration

- Chairside and lab-based setups

Why Dental Milling Machines Are a Game-Changer in Smile Restoration

Dental milling machines are driving major advances in modern dental procedures. These machines are transforming the delivery of care by offering unmatched precision, speed, and customization, all while enhancing the patient experience and reducing costs.

Precision

High-resolution milling technology allows restorations to be crafted with micron-level accuracy. This ensures a:

- Snug fit

- Superior contact points

- Consistent results

The precise fit also reduces the need for chairside adjustments and improves long-term performance.

Speed

In-house milling enables same-day restorations, allowing clinics to produce crowns, bridges, and inlays in just one appointment. This rapid turnaround is particularly valuable in emergency or time-sensitive cases, helping to free up scheduling for more patients.

Cost-Effectiveness

While the initial investment in a milling unit may seem high, the long-term savings are substantial. By reducing reliance on external dental labs, practices eliminate:

- Recurring outsourcing costs

- Shipping fees

- Delays

Over time, the machine pays for itself.

Customization

Every patient is different, and milling machines support full customization of color, shape, and material. Clinicians can match the patient’s:

- Natural tooth anatomy

- Esthetics

- Bite requirements

This improves function, comfort, and visual appeal.

Patient Satisfaction

Faster treatment times, fewer appointments, and better-fitting restorations result in happier patients. Many clinics report higher case acceptance rates and improved reviews after introducing in-house milling capabilities.

Precision dental milling has become a defining feature for forward-thinking practices. Dentists committed to offering high-quality cosmetic and restorative care now view digital milling as an essential part of their workflow. It enables control, consistency, and speed that today’s patients expect.

Key Features to Look for in a Dental Milling Machine

Investing in dental milling technology requires more than choosing a popular brand. It demands a thorough evaluation of key machine features that influence:

- Day-to-day workflow

- Restoration quality

- Long-term value

These features determine how efficiently your practice can fabricate restorations and how well you can serve your patients.

Milling Accuracy

Accuracy is the foundation of high-quality restorations. Machines with micron-level precision, often within 5 to 10 microns, are ideal. Such accuracy ensures:

- Tight margins

- Correct occlusion

- A natural fit

For procedures involving crowns, bridges, or implant abutments, precision is non-negotiable. It reduces chairside adjustments and leads to more predictable outcomes, saving time and increasing patient satisfaction.

Material Versatility

A versatile milling machine must be able to accommodate a wide range of materials. Look for models capable of milling:

- Zirconia

- Lithium disilicate

- PMMA

- Composite resin

- Wax

- Titanium

This flexibility enables clinicians and lab technicians to fabricate a wide range of restorations using a single system. Additionally, the ability to support both wet and dry milling expands the range of what can be produced, from same-day crowns to long-span bridges and hybrid prosthetics.

Automation and Software Integration

Today’s leading machines feature high levels of automation, including automatic tool changers, blank holders, and calibration systems. These features reduce human error and technician fatigue. Seamless integration with CAD/CAM software is equally vital.

Machines that are compatible with your design system ensure smooth file transfers and real-time design modifications. Smart automation:

- Boosts consistency

- Minimizes rework

- Increases productivity

Maintenance and Reliability

Downtime impacts both revenue and reputation. Prioritize machines known for their:

- Durability

- Minimal maintenance needs

- Built-in diagnostic tools

Preventive maintenance alerts, easy-to-clean parts, and strong manufacturer warranties can help machines last longer and work well. Choosing a trusted supplier like Shinoda Dental, which offers reliable service and training, adds even more value.

Speed and Production Capacity

In high-volume practices or labs, speed is crucial. Some chairside machines can produce a single crown in under 10 minutes. Others can mill multiple restorations in one cycle without sacrificing quality.

High-capacity units allow dental labs and multi-operatory clinics to maximize output while maintaining precision. Faster milling means better efficiency and shorter patient wait times, improving patient experience and practice profitability.

Evaluating these five core areas, milling accuracy, material versatility, automation, maintenance, and speed, will help you select the right machine for your clinic or lab. A well-chosen system will:

- Align with your workflow

- Improve patient outcomes

- Position your practice for scalable growth in a digitally driven market.

Top 5 Dental Milling Machines Offered by Shinoda Dental

Shinoda Dental offers a curated selection of the industry’s most advanced dental milling units. Engineers design each machine for precision, speed, and compatibility with a wide range of materials and workflows.

Let’s explore the top five options that dental professionals trust to deliver high-performance results every time.

1. Dentsply Sirona CEREC Primemill Milling Unit

The CEREC Primemill is designed for high-speed chairside milling. It combines cutting-edge grinding and milling modes to maximize efficiency and precision.

Dentists can achieve excellent clinical results with minimal effort, thanks to its intuitive interface and automated features. Let’s look at its features:

- Compatible with the CEREC system

- Mill crowns in under five minutes

- Automatic block size detection

- Excellent fit and finish

It’s ideal for same-day restorations in a busy dental office.

2. Roland DWX-52DCi Dental Milling Machine

Known for its automation and consistency, the DWX-52DCi is a lab-friendly and powerful option. It is engineered to support continuous workflows and accommodate high-output demands with minimal manual intervention. This machine excels in multi-material environments, offering repeatable accuracy and enhanced productivity.

Below are the key features that make the DWX-52DCi a strong contender for busy dental labs:

- Disc changer holds six materials

- Automatic tool changer with 15 tools

- Built-in camera for material tracking

- Supports zirconia, PMMA, wax, and more

It’s excellent for multi-unit and multi-material workflows.

3. Roland DWX-53DC Dry Dental Milling Machine

Designed for dry milling, this unit offers enhanced usability and material compatibility. It delivers clean, efficient milling results while eliminating the need for water filtration or drying time. The user-friendly design allows operators to switch materials quickly and maintain optimal machine performance.

Here are the standout features that make it ideal for dry material workflows:

- New DWINDEX performance visualization

- 3 mm tools enable precision detailing

- An optional ionizer reduces static

- Less maintenance required

It’s ideal for high-throughput labs that focus on dry materials.

4. Planmeca PlanMill 35

An intuitive milling machine optimized for versatility. It supports a wide range of workflows and easily adapts to both complex and straightforward restorations. Designed for both wet and dry milling, it ensures maximum flexibility in material usage.

The following features highlight why the PlanMill 35 is a top choice for scalable clinical needs:

- Processes wet and dry materials

- 5-axis milling for complex geometries

- Self-cleaning spindle and automatic tool changer

- An open system integrates easily with third-party CAD

It’s ideal for clinics seeking a scalable and flexible solution.

5. Vhf Z4 4-Axis Milling Machine

Compact yet powerful, the VHF Z4 delivers precision and speed. Its advanced 4-axis milling capabilities enable the efficient production of high-quality restorations in a compact footprint. The intuitive interface and quick milling cycle make it ideal for use at the chairside.

Here are the core features that make the vhf Z4 a standout option for fast, reliable milling:

- Wet milling for glass ceramics and composites

- Automatic 6-tool changer

- RFID tool tracking

- Fast 10- to 15-minute milling cycle

It’s ideal for chairside applications where time matters.

How Shinoda Dental Supports Dentists Beyond the Sale

Shinoda Dental, based in California, offers more than just advanced dental milling equipment. The company has built a reputation on:

- Long-term relationships

- Personalized service

- Post-sale support

We equip dental professionals to succeed in a competitive and digital-first environment. If you are buying your first dental milling machine or growing your lab, Shinoda Dental will partner with you.

Installation and Setup

Every dental milling system purchased through Shinoda Dental comes with professional setup and calibration. Our expert technicians do the following:

- Install the unit on-site

- Configure the settings

- Integrate the machine with your CAD/CAM system

- Test its performance

This ensures your team starts with a machine that is fully operational and tailored to your existing workflow.

Training Services

After installation, Shinoda Dental provides extensive training to dentists, hygienists, and laboratory technicians. This includes:

- Hands-on learning

- Video tutorials

- Live remote support to walk your team through every step of the process, from file input to final milling.

By the end of the training, staff are equipped to operate the system with confidence and efficiency.

Technical Support

Technology is only as good as the support behind it. Shinoda Dental’s U.S.-based technical support team is available to help with:

- Software updates

- Connectivity issues

- Troubleshooting

- Unexpected malfunctions

Quick response times and in-depth expertise help reduce downtime and keep your clinic or lab operating smoothly.

Maintenance Plans

Dental milling machines are precision tools that require ongoing maintenance. Shinoda Dental offers preventative maintenance plans that include:

- Periodic system checkups

- Tool replacements

- Software updates

- General upkeep

These plans are designed to minimize long-term wear and tear, helping practices maximize the life of their investment.

Tailored Recommendations

One of Shinoda Dental’s standout strengths is its consultative approach. Our team takes time to understand:

- Your patient volume

- Restoration types

- Practice goals

- Available space

They give you tailored recommendations. These match you with the best machine for your needs. This could be a small chairside solution or a high-throughput lab model.

Shinoda Dental goes beyond being a supplier; we act as an extension of your team. Our hands-on approach, proactive support, and dedication to education help practices navigate digital transformation with ease.

By working with Shinoda Dental, you can use advanced equipment. You also get a dependable support system. This helps ensure long-term success.

Our goal is not just to sell equipment; it is to provide a comprehensive solution. We want to help you deliver faster, better, and more reliable care for every patient you treat.

The Future of Smile Restoration: Dental Milling Machines Are the Smart Investment

Dental milling machines are redefining what’s possible in smile restoration. They empower clinics and labs to offer fast, accurate, and fully customized solutions in-house. Whether you’re producing crowns, bridges, or implant components, precision dental milling is the future of restorative dentistry.

Dentists who invest now position their practices for long-term success. Shinoda Dental offers a carefully curated lineup of Top dental milling machines backed by industry expertise and full support.

Are you ready to take the next step? Contact Shinoda Dental today for expert advice, equipment demonstrations, and comprehensive support.