No products in the cart.

Article

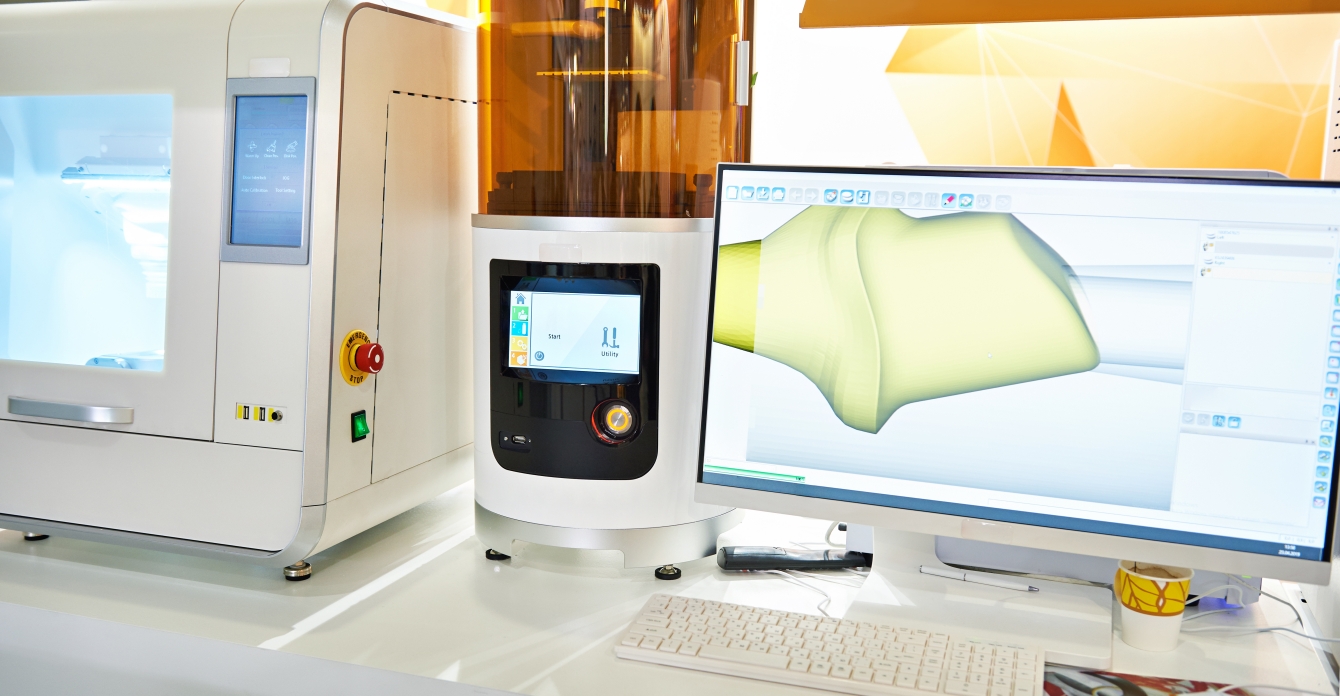

Choosing the Right VHF Milling Machine for Your Dental Clinic: A Guide

Integrating advanced technology is no longer a luxury in today’s rapidly evolving dental industry. It’s a necessity.

One such technological advancement is the VHF milling machine. A tool that empowers dental professionals to craft precise restorations in-house. But with various models and features available, how do you determine the best fit for your clinic?

This guide will help you choose the best VHF dental milling machine. Improving efficiency, precision, and profits for your practice is possible. Keep reading to discover which VHF model can transform your workflow and maximize your clinic’s potential.

Understanding VHF Milling Machines

A dental milling machine uses computer-aided design and manufacturing (CAD/CAM) technology to make dental restorations like crowns, bridges, inlays, onlays, and veneers. These machines carve restorations from solid material blocks by employing subtractive manufacturing techniques, ensuring high accuracy and fit.

Key applications of high-precision dental milling machines include the fabrication of:

- Crowns and bridges

- Onlays and inlays

- Veneers

All of these require precision and customization to meet individual patient needs.

Crowns and Bridges

These restorations replace damaged, decayed, or missing teeth. Crowns fully cover a compromised tooth to restore its shape, size, strength, and appearance.

Bridges fill gaps by anchoring artificial teeth to adjacent natural teeth or implants, providing functional and aesthetic improvements.

Onlays and Inlays

Inlays conform to a tooth’s grooves, while onlays spread over one or more cusps. Both are conservative alternatives to full crowns and ideal for restoring moderately damaged teeth. They are custom-milled for a precise fit, offering strength and durability with minimal removal of natural tooth structure.

Veneers

Veneers are thin, custom-crafted shells that are bonded to the front surfaces of teeth to enhance their appearance. Cosmetic dentistry commonly uses them to correct discoloration, minor misalignment, chips, or gaps.

Precision-milled veneers ensure a natural look and comfortable fit. This improves a patient’s smile with minimal invasiveness.

Advantages of in-house milling include:

- Efficiency: Reduce turnaround times by producing restorations on-site

- Precision: Achieve a higher degree of accuracy tailored to individual patient needs

- Cost savings: Minimize expenses associated with outsourcing to external labs

- Enhanced patient satisfaction: Offer same-day dentistry solutions, reducing patient visits and enhancing convenience

Key Factors to Consider When Choosing a VHF Milling Machine

Before making a purchase, it’s essential to understand how different VHF models align with your practice’s unique needs. Each machine offers distinct advantages, so a thoughtful comparison is vital.

Selecting the right VHF dental milling machine requires careful evaluation of several critical factors discussed below.

Material Compatibility

When choosing a Top dental milling machine, the types of materials it supports can impact your clinical offerings. Different restorations require different materials, each with its own strengths. Understanding your clinic’s most common use cases will guide you toward the most compatible system.

- Zirconia: Known for its strength and aesthetic appeal

- PMMA: Ideal for temporary restorations and dentures

- Titanium: Used for implants and abutments due to its biocompatibility

- Composites and ceramics: Offer aesthetic solutions for various dental applications

Ensure the machine supports the materials predominantly used in your practice. Consider if your restorations will include a mix of wet and dry milling materials, such as glass ceramics or titanium.

Wet vs. Dry Dental Milling

Whether wet or dry, the milling method you choose affects the materials you can use and the final quality of restorations. Understanding the difference between the two helps ensure you select a machine that supports your workflow.

Let’s explore how these two methods compare compatibility, performance, and maintenance.

Wet Milling

Wet milling utilizes a liquid coolant for materials like glass ceramics and composites. It prevents overheating, extends tool life, and provides smoother finishes.

Wet milling is often the preferred method for esthetic restorations due to its ability to maintain material integrity and surface quality. However, it requires more maintenance due to fluid management systems and the need for regular cleaning.

Dry Milling

Dry milling does not require a coolant, which is ideal for materials like zirconia. Dry systems typically produce less waste and require less maintenance.

They are generally more energy-efficient and cost-effective over time, making them suitable for high-throughput environments where speed and simplicity are priorities.

Some models offer flexibility between wet and dry dental milling, allowing users to toggle between the two for optimal results.

Precision and Speed

Precision and speed are two of the most critical performance indicators for any milling machine. Your ability to quickly produce detailed, accurate restorations can affect patient satisfaction and clinical efficiency.

Let’s examine how these elements influence the selection of the right machine.

- Spindle RPM: Higher RPM leads to smoother surfaces and fine detailing

- Axes: 5-axis systems enable more complex geometries and angles, perfect for advanced restorations

- Milling time: Evaluate how long it takes to produce single and multiple units

Automation and User-Friendliness

Automation features can save time and reduce errors, especially in busy clinical environments. A user-friendly design ensures that your team can operate the machine efficiently without extensive training.

Let’s examine which automation tools and user experience features make the biggest difference in dental workflows.

- Tool changers: Automated changers improve workflow by switching tools as needed without manual intervention

- Software integration: Ensure compatibility with your CAD/CAM design software, simplifying your workflow

- Ease of use: A straightforward interface reduces training time and operational errors

Size and Footprint

Space limitations should factor into your decision. Smaller practices may benefit from compact units that still deliver quality results.

Larger practices or labs may accommodate machines with larger build volumes and more automation. Consider the following:

- Where to place the machine

- How it will integrate into your existing workflow

Proper planning ensures that the machine enhances efficiency rather than creating congestion.

Cost vs. ROI

Investing in a VHF milling machine is a long-term decision that can impact your clinic’s success. It is important to assess how quickly the investment can pay for itself through enhanced capabilities and reduced outsourcing.

Evaluate the machine’s cost against potential benefits:

- Reduced lab fees

- Increased treatment capacity

- Faster case delivery

Over time, in-house milling can improve your bottom line.

Comparing Top VHF Milling Machines

VHF offers a range of machines suitable for various practice types. Each model supports specific clinical workflows, ranging from single-unit restorations to full-arch rehabilitations. By understanding each machine’s capabilities, dentists can better align their technology investments with practice goals.

Let’s look at how they compare.

1. VHF R5 ($20,999.00)

The VHF R5 is among VHF’s most advanced offerings. It combines powerful capabilities with exceptional automation. The design supports a wide range of restorative procedures while easily handling both wet and dry milling.

- Type: 5-axis milling and grinding machine

- Capabilities: Hybrid (wet and dry) with a ten-fold blank changer

- Materials: Zirconia, PMMA, titanium, glass ceramics, composites

Its features include:

- Direct Disc Technology for tool-free blank clamping

- Direct Clean Technology for quick switchovers

- Water-cooled spindle for continuous performance

This model is ideal for high-volume dental labs and multi-practice clinics.

2. VHF Z4 ($11,599.00)

The VHF Z4 is a compact yet powerful solution for clinics prioritizing efficiency and aesthetics. Particularly well-suited for same-day treatments, this approach helps practices deliver high-quality restorations in a single visit.

- Type: 4-axis wet milling machine

- Capabilities: Same-day dentistry milling machine

- Materials: Glass-ceramics, composites, pre-milled titanium

Its features include:

- High-speed, high-precision output

- Simplified operation

- Compact and stylish design

The VHF Z4 is best for single-visit restorations and cosmetic dentistry clinics.

3. VHF E5 Dental Milling Machines ($20,990.00)

The VHF E5 is for dentists who want to bring digital milling into their practice without a steep learning curve. It offers a streamlined, dry milling experience in a compact, cost-effective package.

- Type: 5-axis dry milling machine

- Capabilities: Plug-and-play dry system with no need for compressed air

- Materials: Zirconia, PMMA, wax, composites

Its features include:

- Integrated DENTALCAM software

- Compact design for small clinics

- Capable of milling up to six blocks

This machine is best for cost-conscious clinics, starting with digital milling.

4. VHF K5+

The VHF K5+ is engineered for precision-focused practices that demand consistent results across a wide range of materials. Its robust design and advanced features make it an excellent choice for high-throughput environments.

- Type: 5-axis dry milling

- Capabilities: High-speed milling with advanced spindle technology

- Materials: Zirconia, PMMA, wax, composites

Its features include:

- 16-position automatic tool changer

- Open system compatibility

- Rigid construction for vibration-free milling

This model is best for medium to large practices, prioritizing precision and versatility.

Which VHF Milling Machine Is Right for Your Practice?

- Choosing a dental milling machine depends on your clinic size, patient demand, and budget. Also, it’s essential to think about your long-term goals, such as: Expanding your service.s

- Transitioning to fully digital workflows

Matching the right equipment with your objectives ensures a more efficient and profitable investment.

For Same-Day Solutions and Smaller Spaces

Clinics that prioritize speed, patient convenience, and a compact footprint should consider the VHF Z4 or VHF E5. The Z4 is ideal for producing high-quality, same-day restorations, such as crowns and veneers, with its wet milling capabilities, making it a strong choice for both cosmetic and restorative applications.

The E5, on the other hand, offers dry milling in a simplified, plug-and-play format. This is ideal for smaller practices entering the digital dentistry space. It doesn’t require a complex setup or compressed air.

For High Output and Material Flexibility

Larger dental practices and labs that handle a high volume of cases should opt for the VHF R5. It can mill different materials easily. Hic modelus praebet molendum hybridum (humido et sicco), mutatio automatica blankorum, et subsidium pro variis materiis, inter zirconiam, titanium, et ceramicas vitreas.

For Consistent Dry Milling at Scale

If you work with dry materials like zirconia and PMMA, choose the VHF K5+. It offers reliable and fast performance. The K5+ uses advanced spindle technology and a 16-position automatic tool changer. Its precision-engineered parts ensure accurate results every time, even at large scales.

An excellent investment option exists for clinics or labs that require robust dry milling capabilities. It requires little maintenance and offers long-term reliability.

Benefits of Investing in a VHF Milling Machine

By investing in the right milling equipment, your clinic can unlock greater control and speed in restorative workflows. The benefits go beyond convenience. They translate into better patient experiences and stronger clinical outcomes.

Let’s examine the benefits of incorporating a VHF dental milling machine into your clinic.

Faster Turnaround Times for Lab-Quality Restorations

In-house milling reduces the time needed to produce crowns, bridges, veneers, and other restorations. Researchers can now complete tasks that once took them days or even weeks to complete through an external lab in just hours. This allows dentists to deliver high-quality results in a single appointment.

Improved Restoration Accuracy and Aesthetics

VHF milling machines provide accurate, computer-controlled results. This ensures that restorations fit well and match the natural shape of the patient’s teeth. This level of detail enhances both function and appearance, resulting in outcomes that meet high clinical and cosmetic standards.

Reduced Dependency on External Labs

By investing in a reliable dental CAD/CAM milling machine, practices can limit their reliance on third-party labs. This improves workflow efficiency and gives clinicians full control over:

- Production timelines

- Material selection

- Quality assurance

Higher Patient Satisfaction With Same-Day Treatments

Patients appreciate the convenience of same-day restorations, eliminating the need for temporary crowns and multiple visits. The ability to complete treatment in one session enhances patient trust and improves overall satisfaction with the dental experience.

Boosted Revenue Through Additional Services

In-house milling allows for more profitable procedures, including cosmetic makeovers, implant restorations, and full-arch rehabilitations. Over time, these services contribute to higher case acceptance rates and increased practice revenue.

These machines streamline your workflow and help modernize your clinic.

Conclusion: Make a Smart Investment With the Right VHF Milling Machine

Choosing the right VHF milling machine for your dental clinic is essential. It helps you stay competitive and provide high-quality care. Each model caters to different needs, from compact units for chairside milling to advanced systems for multi-material production.

Shinoda Dental proudly serves dental professionals across the U.S., including clinics in California and beyond. Customers recognize Shinoda Dental for its high-quality products, dependable customer service, and quick shipping. They provide the solutions you need to grow your practice.

Ready to elevate your practice? Browse Shinoda Dental’s range of VHF Dental Milling Machines today and find the best fit for your digital workflow.