Subtotal: $22,999.00

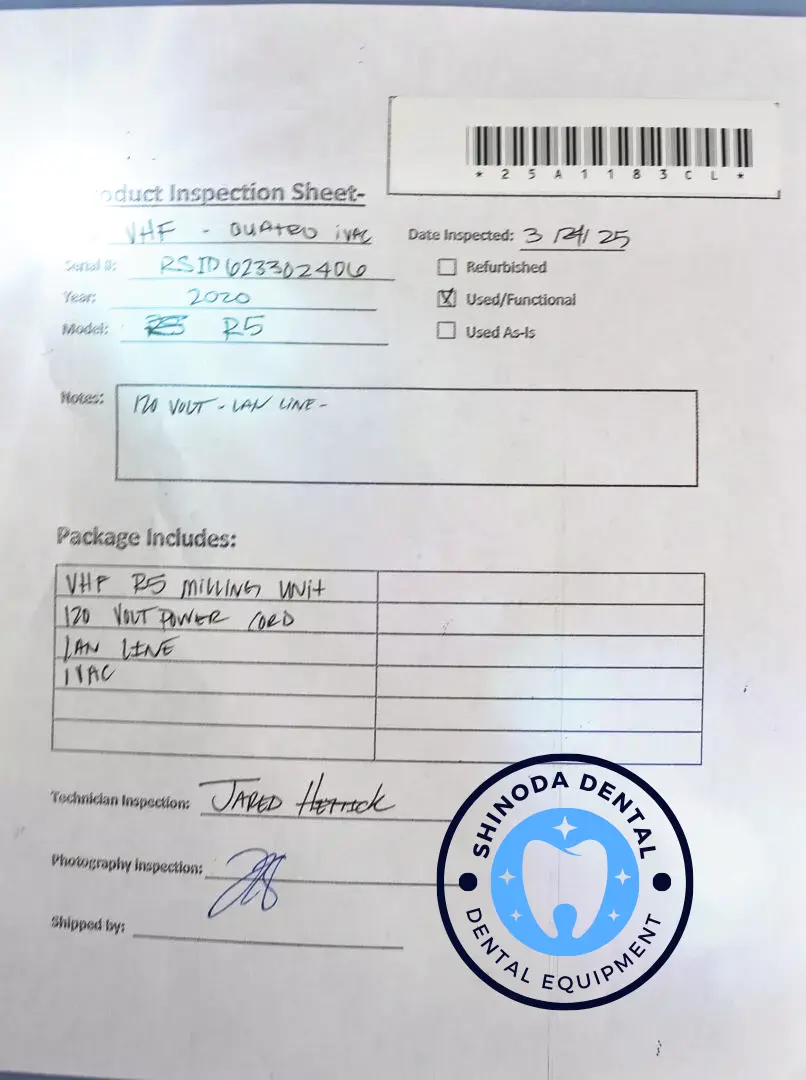

VHF R5 5-Axis Dental CAD/CAM Milling Machine

$40,999.00 Original price was: $40,999.00.$20,999.00Current price is: $20,999.00.

The VHF R5 5-Axis Dental CAD/CAM Milling Machine provides high-precision milling for dental restorations, utilizing advanced 5-axis technology. Ideal for dental labs seeking efficient, accurate, and versatile milling solutions.

In stock

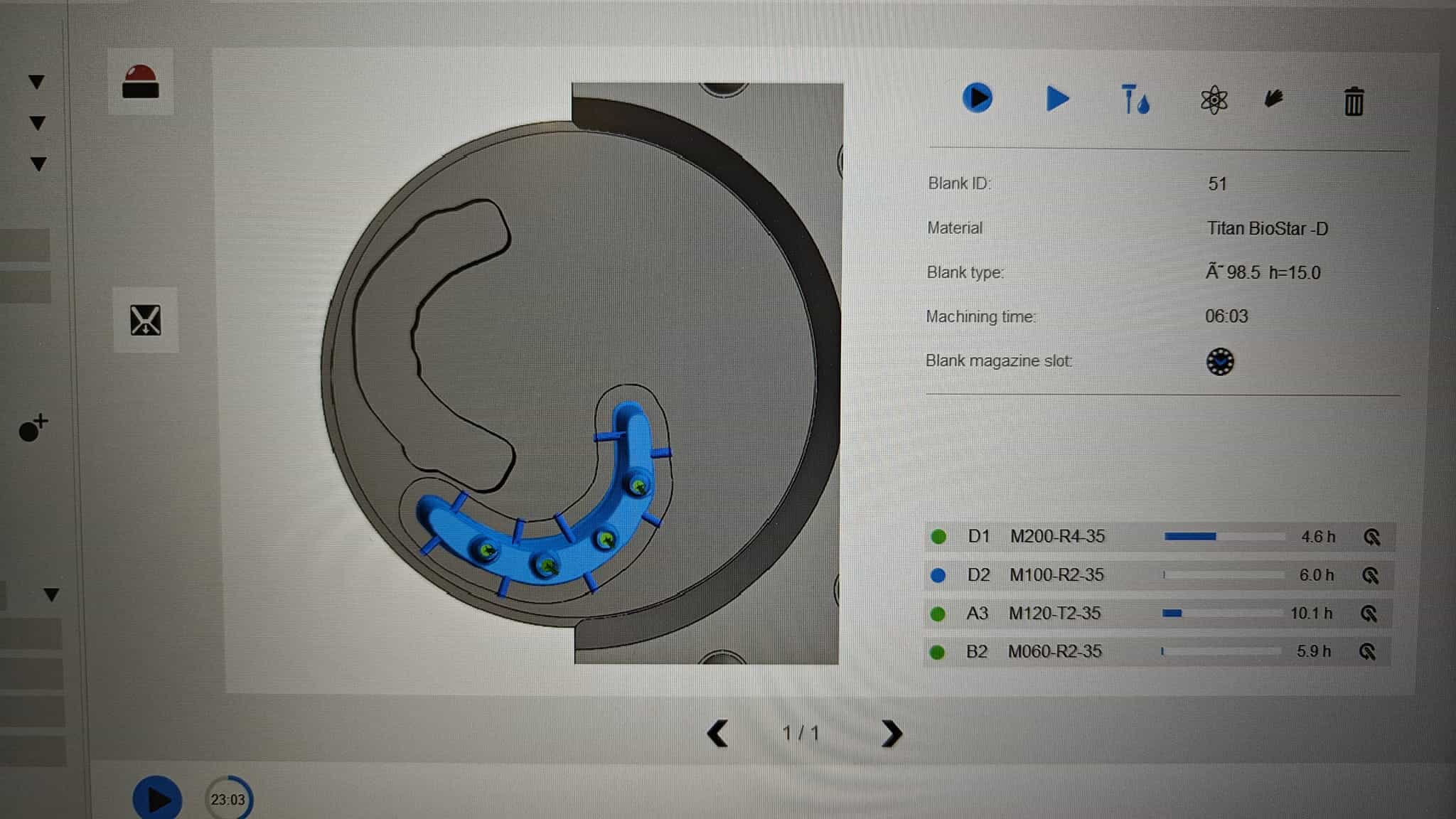

The VHF R5 5-Axis Milling Machine redefines automation and productivity in dental labs. Equipped with an integrated vacuum system and an automatic 10-disc changer, the R5 enables continuous, unattended milling. It supports both wet and dry milling and can handle materials such as titanium, zirconia, PMMA, and more.

The R5’s powerful 800-watt spindle operates at up to 80,000 RPM, ensuring high-speed precision milling. Its easy-to-use touchscreen and advanced CAM software make operation simple. The built-in camera system allows real-time monitoring of the milling process.

High-end dental restorations with the speed and efficiency of automation

The VHF R5 5-axis dental mill is an automated tool for wet and dry milling. It is made to handle many dental tasks with reliability and precision.

The VHF R5 can hold 150 kg while taking up little space. It has a linear axis accuracy of ±0.003 mm. This means it provides ultra HD accuracy in a way that fits your lab.

Unrivaled Wet & Dry Machining

Whether you are a dental clinic or lab, with the R5 from VHF Germany, you can simply process everything, 24 hours a day. R5 is a 5-axis system, designed and engineered to be fast and effortlessly between wet and dry machining. Thanks to the DirectClean™ Technology*, the R5 cleans and dries itself between jobs due to a groundbreaking package that includes an ionizer, self-cleaning and built-in dryer. Moreover, the unique material loading with DirectDisc™ Technology* of the changer with up to ten discs saves you valuable time.

Features

Highest precision

- Restorations in Ultra HD

- High-precision spindle with 800 watts of power and 80,000 rpm

- 3 μm repetition accuracy

Tremendous stability

- Mills and grinds the toughest materials on the market including all titanium and CoCr materials

- Proven industrial quality

- Solid cast-body for minimum vibrations

Absolute independence

- Sheer unlimited material variety in 98 mm disc format, around 40 block materials, and

- 800+ titanium and CoCr prefab abutment blanks

- Covers the broadest range of indications, due to ± 35° rotation angle in the 5th axis, and up to 40 mm disc height

Outstanding reliability

- 100 % engineered and manufactured in Germany

- Comprehensive sensor technology to monitor all vital system functions

- 24-month warranty

Highly economical

- One of the fastest machines on the market

- Revolutionary material loading with directdisc Technology (patent pending)

- Automatic changer holds up to 10 discs, 60 blocks, or 60 prefab abutments

- Webcam in working chamber for remote monitoring and service

- directclean Technology enables wet and dry on the fly: ionizer, self-cleaning and built-in dryer (patent pending)

- Drilling of screw access channels – saves costs for “meso” blocks

- Very easy operation via dentalcam software with directmill Technology – included in scope of delivery and without license fees

Key Highlights

Maximum automation

R5 can process without interruption up to 10 discs or 60 blocks or abutments. With a tenfold blank changer for wet and dry milling and grinding, the R5 brings revolutionary approaches to the production of dental prostheses. The R5 disc changer is a robot arm with a pneumatic gripper for swift changing. The removable tool magazine holds 16 tools and the tool changer does not require user intervention.

Utmost accuracy

The R5 with linear axes X-/Y-/Z-axis swivels the high-frequency spindle (B axis) by up to ±35°, therefore the workpiece holder only needs one moving axis (A axis). This makes the entire system gain stability and have the lowest vibration operation. The repetition of the linear axes of ±0.003 mm ensures a unique precision in ultra HD.

Material accessibility

VHF’s R5 covers the broadest range of materials in 98 mm disc format, 38 block materials, and over 800 titanium and chrome-cobalt prefab abutment blanks.

Benefits

Powerful and Robust

R5, with 800 watts of power and 80,000 RPM, is entirely engineered and manufactured in Germany for higher dental lab productivity with proven industrial quality.

It mills the toughest materials on the market including titanium (Ti) and cobalt-chrome (CoCr).

Game-Changing Technology

Thanks to the DirectClean™ Technology, the R5 is equipped with an ionizer that reduces the static charge from human agents, self-cleaning, and a built-in dryer making it extremely easy to maintain and operate, thus saving significant labour time.

Cost-Effective

- High-speed spindle & superfast milling strategies for restorations in no-time

- Wide range of materials that are easy to load

- R5 has the ability to drill screw access channels so that you don’t have to keep a double inventory of regular and pre-milled blocks

- R5 grinds and mills with clear water, no additives needed (except for titanium)

Materials

- Zirconia

- Titanium

- Cobalt Chrome (CoCr)

- WAX / Plastics

- Composites

- Glass ceramics

Applications

- Abutment

- Full Denture

- Model

- Model Casting

- PreMilled Abutment

- Splint

- Telescopic Technology

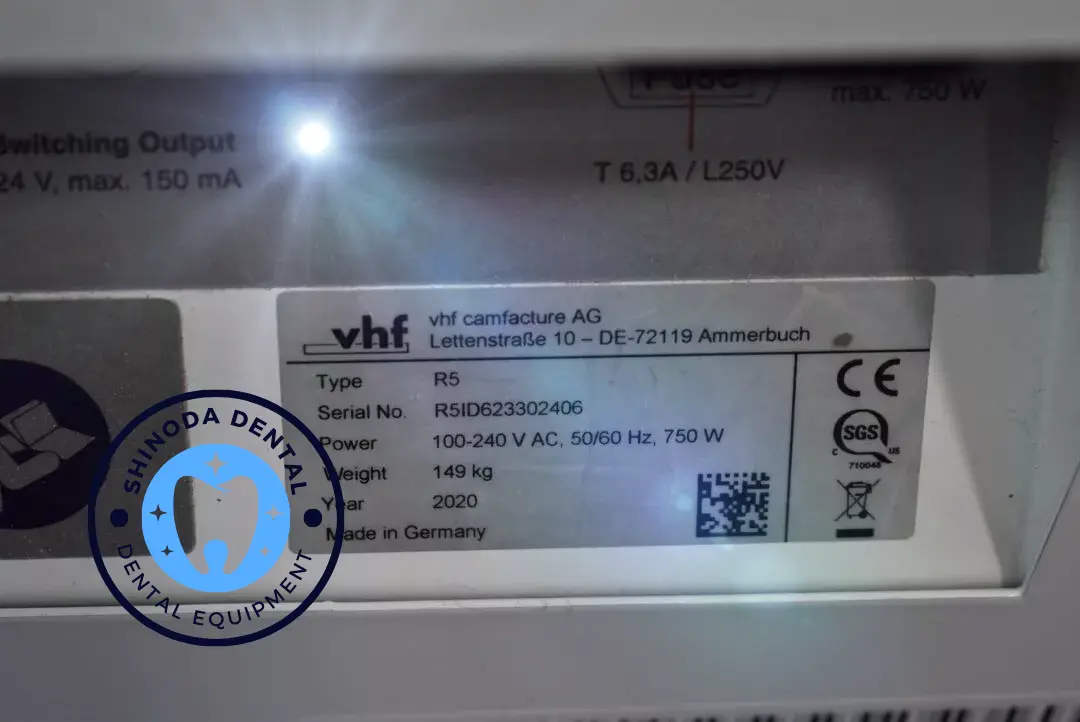

Technical Specifications

Software | Included VHF DentalCAD software – no annual license fee needed |

Dimensions (W/D/H) | 580 × 600 × 700 mm with closed flap 580 × 720 × 880 mm with open flap |

Weight | 150 kg |

Construction base | Machine bed made of solid cast aluminum body |

Housing | Sheet steel, white high-gloss lacquer finish with working chamber door and flap combination for blank changer/cooling liquid tank |

Number of axes | 5 (five) |

Linear axes X-/Y-/Z-axis |

|

Rotary axis A-axis |

|

Rotary axis B-axis |

|

Control unit |

|

Lighting | RGB LED lighting with status display |

Camera system | Integrated in the working chamber for easy remote support and possibility of internal recording |

Spindle power |

|

Bearing | 4-fold hybrid ceramic ball bearing · concentricity deviation at inner cone < 3 μm |

Collet | Stainless steel collet with ceramic coating for tools with a shank diameter of 3 mm and max. 40 mm total length |

Connection requirements | Compressed air 6 bar · 100 l/min · 8 bar · 110 l/min · Air purity according to ISO 8573-1:2010Power 100-240 volts · 50/60 Hz, 750 wattsExtraction System Filter class M, 3500 l/min extraction capacity at 220 hPA Data |

Operating temperature | Between 10 °C and 35 °C |

Reference

Amann Girrbach Ceramill Motion 3 Milling unit

Amann Girrbach Ceramill Motion 3 Milling unit