No products in the cart.

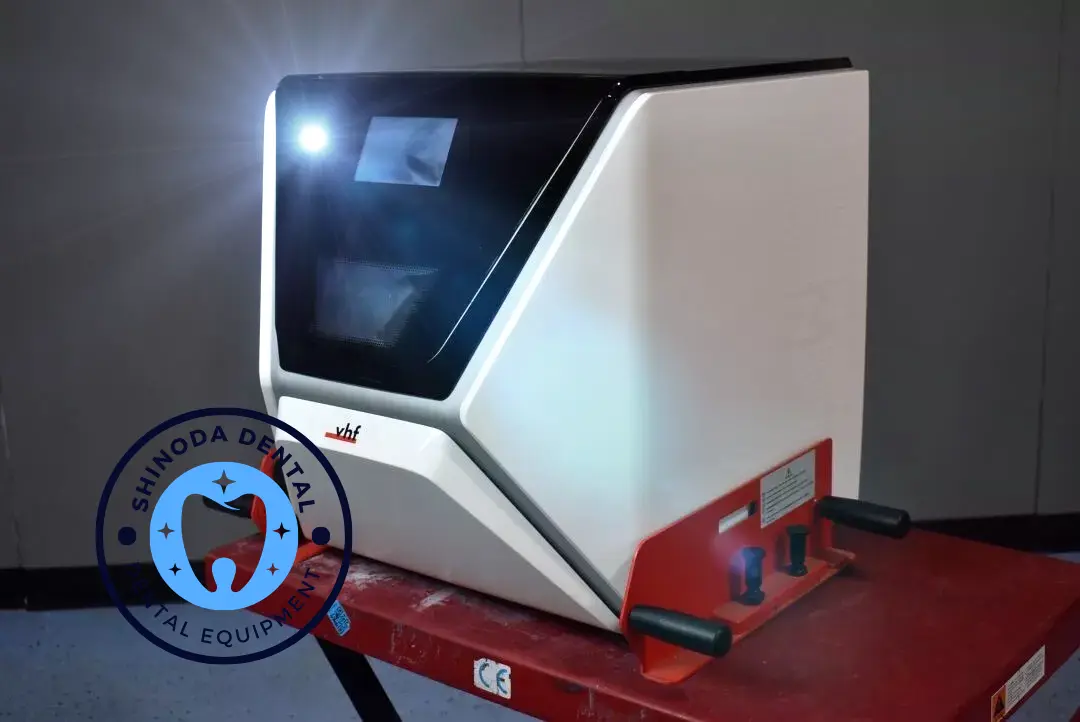

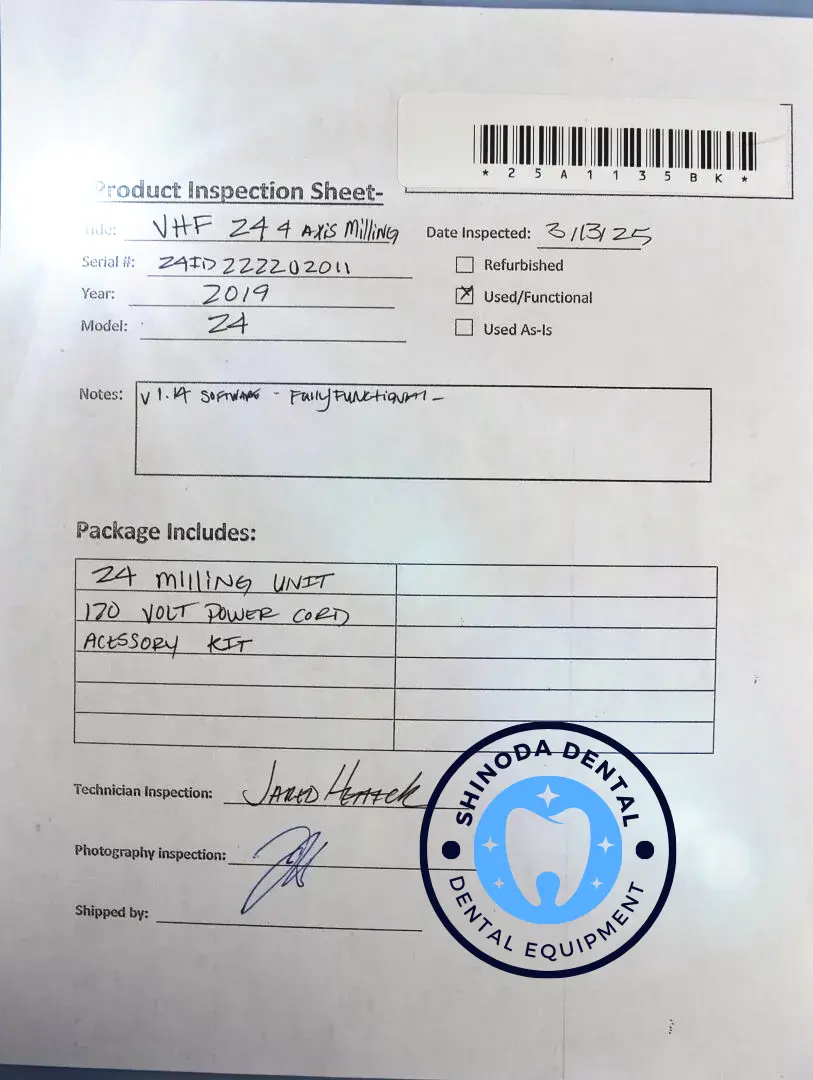

VHF Z4 4-Axis Dental CAD/CAM Milling Machine

$16,599.00 Original price was: $16,599.00.$11,599.00Current price is: $11,599.00.

The VHF Z4 4-Axis Dental CAD/CAM Milling Machine delivers efficient and precise milling for dental restorations. Designed for dental labs seeking dependable performance with versatile 4-axis technology.

In stock

The VHF Z4 4-Axis Milling Machine is built for speed and accuracy. It is the ideal choice for same-day restorations. This chairside machine is capable of wet milling ceramics, composites, and glass ceramics with an accuracy of ±25 µm.

The Z4 has a powerful spindle that runs at up to 100,000 RPM. It also has an automatic 8-position tool changer for smooth operation. Its compact footprint and intuitive touchscreen interface make it ideal for dental practices that prioritize patient care and efficiency. The Z4 also integrates seamlessly with CAD/CAM workflows, allowing for rapid design and milling.

The VHF Z4 dental mill is a groundbreaking tool for same-day digital dentistry. The system provides the accuracy, reliability, and range of materials that dentists need. It allows for restorations in just one session.

Grind and mill with the Z4 in Ultra HD for great results. Connect with popular software and intraoral scanners for a full workflow.

Features:

Highest precision

- Milling and grinding in ultra HD

- Proven industrial quality

- 3 microns repetition accuracy

Extremely economical

- Clear water – no additives necessary

- Mill screw-access channels, to save costs for “meso” blocks

- Automatic changer for 6 tools

- Self-opening working chamber door and drawer

- Easy to learn, easy to operate

- 24 months warranty

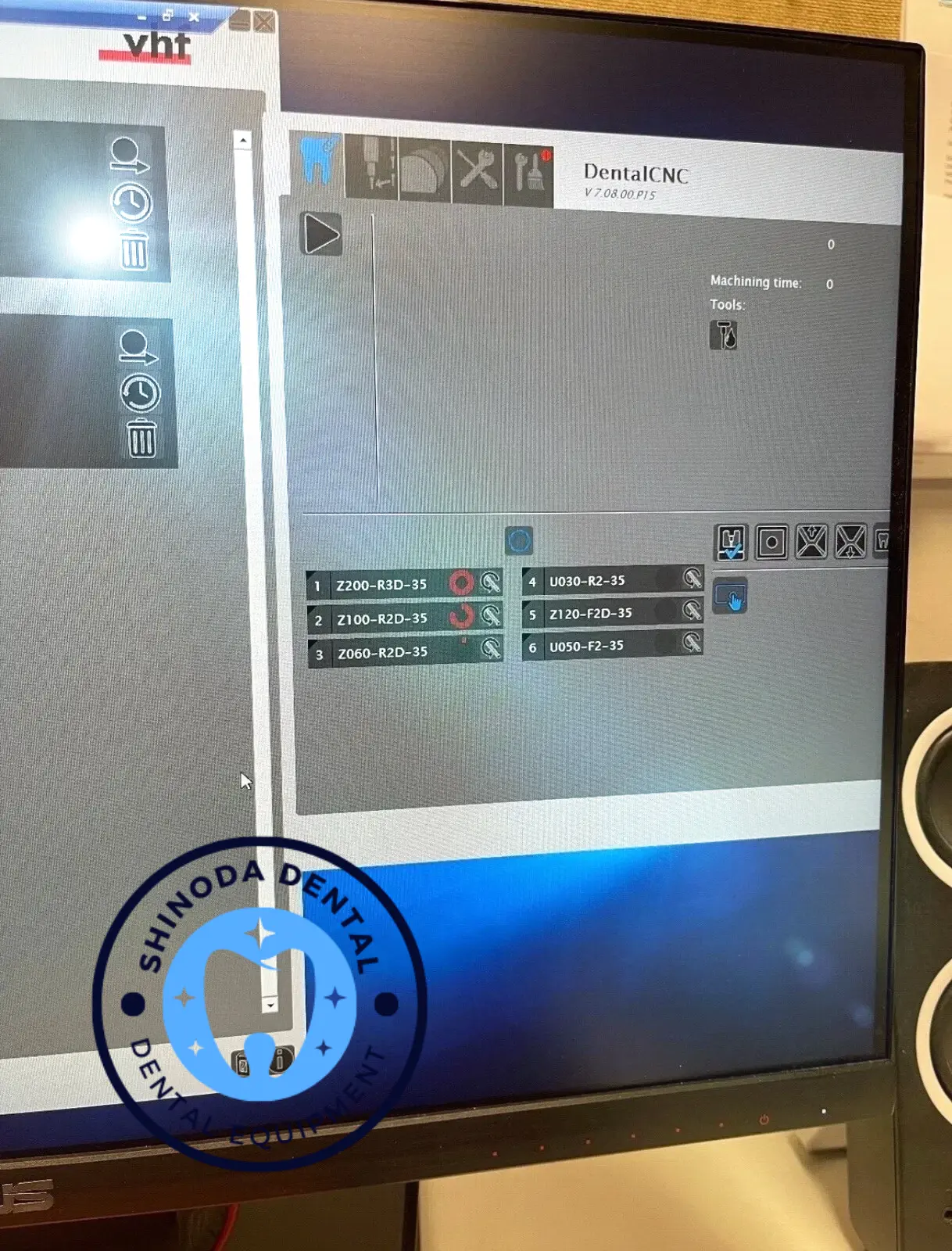

- CAM software included

- Tool starter set included

Fastest production

- Restorations in under 10 minutes

- 2-second block insertion

- 100,000 RPM electrical high frequency spindle

Complete Independence

- 38 block materials from 20 manufacturers – and growing

- 800+ prefab titanium abutment blanks from 11 manufacturers

- Validated with all established scanners and design software

- Fully integrated workflow with TRIOS Design Studio (3Shape), DWOS chairside (Dental Wings) and exocad ChairsideCAD*

- Integrated PC with touch screen and Wi-Fi – no laptop or tablet necessary

- Built-in compressed air – no compressor needed

*Material and indication availability may vary by CAD provider—full range of indications and materials available in STL workflow.

Benefits and Advantages

Highest Precision & Fastest Production

- Milling and grinding in Ultra-HD

- Proven industrial quality

- 3 microns repetition accuracy

- Restorations in under 10 minutes

- 2-second block insertion

- 100,000 RPM electrical high-frequency spindle

Maximum Independence

- 38 block materials

- 800+ prefab titanium abutment blanks

- Compatible with all established scanners and design software

- CAM software included

- Integrated PC with touch screen, which means that no laptop/desktop is required

- Wi-Fi connectivity allows for positioning the mill wherever you want in your dental office.

- Built-in compressed air

Intelligent and Intuitive

Z4 uses different-sized tools.

- Automatic changer for 6 tools with haptic tool length detection and tool breakage monitoring

- 5 tool changer inserts (6 tools each) coded for different applications or materials

- Color-coded tool magazines

Cost Saving and Performance

- Widest choice of materials

- Flexibility in intraoral scanners

- Seamless workflow due to Z4’s integration with 3Shape™, DWOS Chairside™ and Exocad ChairsideCAD™

- Z4 doesn’t require additives as it purely operates with clear water

- Z4 can mill even titanium abutments due to its sturdy build.

- Produce your titanium implant abutments using prefab abutment blanks. For hybrid implant restorations such as a screw-retained crown or hybrid abutments, standard blocks can be used, as the Z4 drills the screw channel itself

- All blocks with the most commonly used CEREC® or universal mandrel can be loaded into the Z4

Smart. Silent. Sturdy

- Z4 reminds you and gives detailed instructions on cleaning and maintenance

- Easy-cleaning coating

- The inside of the milling chamber is coated with non-stick paint that lets the water just drip off.

- Noise reduction. Silent mode is available.

- Extra thick layers of sound-absorbing foam around the milling chamber helps to reduce noise

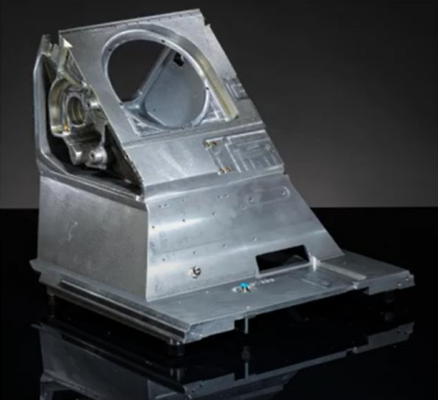

- Massive machine bed of aluminum cast to minimize vibrations and distortions

- Finely balanced spindle

- State-of-the-art controller

Safe Operation

- Z4 checks if the right tool magazine is loaded

- It measures the blocks to ensure that the right size is being loaded

- One cannot open the mill during operation due to its patient protection lock mode

- A service camera is incorporated so that the service technicians can review the recorded video stream

Technical Specifications

Construction | Machine bed of massive aluminum cast |

Number of axes | 4 |

Drives | Precise ball screw spindles for the 3 linear axes · motor resolution < 1 μm · ground steel precision guide rails |

Repetition accuracy linear axes | ± 0.003 mm |

Housing | Complete encapsulation of the working chamber with integrated sound insulation · Automatically lockable front cover |

Working chamber illumination/camera system | 2 RGB LED with status indication · integrated camera for support purposes |

Rotary axes | A axis: highest true running accuracy · rotation range: 200° |

Rotary axes – Fixing device | For 1 block with round shank up to 45 × 20 × 20 mm |

Controller | Simultaneous axis control · feed: 0.003 mm/s to 45 mm/s (per linear axis) |

Integrated CAM calculator | Intel® Atom™ E3950, 4 kernels, 1.60 – 2.00 GHz, 8 GB RAM · additional HDMI display interface · Wi-Fi |

Display | 5-inch touchscreen display integrated into the front cover |

Spindle | Rotational speed range up to 100,000 RPM · Peak power (Pmax): 340 Watt · nominal power under periodic operation (S6): 220 Watt · nominal power under continuous operation (S1): 170 Watt · hybrid ceramic ball bearing · concentricity deviation at the inner taper of the precision shaft < 2 μm · sealing air prevents entering of debris or moisture in the bearing area · cone cleaning |

Compressor | No compressor needed |

Power supply | 100 – 240 Volt · 50/60 Hz, max. 750 Watt |

Network | RJ45 socket for Ethernet or integrated Wi-Fi |

Delivery package included | 5 × tool magazines (in the drawer) incl. accessories · power cord · Ethernet network cable (type: straight) · spindle service set · blank holder service set · measuring pin · drill for tool positions (2.8 mm) · calibration set: 1 micrometer, 5 blanks for the production of test and calibration bodies · cleaning set · spare wiper for inspection window · filter service set · printed operating instructions · carrying aid for the transport of the machine · tools for user-replaceable wear parts, Monitor, keyboard, and mouse. Universal CEREC style block holder, FREE Clinux CAD software, 2 full days of immersive training for your milling machine, including a professional factory-trained installer, Tool set starter edition for VHF z4 27 tools |

Reference

Related products

Sale!

Sale!

Sale!

Sale!

Sale!

Sale!

Sale!

Sale!